SIEBTECHNIK TEMA feeders are freely vibrating machines, that is, the vibration amplitude adjusts itself freely to suit the mass ratio of channel box and unbalance mass. Linear-motion channel conveyors are designed with a selectable throw angle and are therefore flexible with regard to the tilt of the conveyor trough, which ranges from horizontal through to steeply tilted.

Our FG (double unbalance gear unit) and FR (unbalance motors) series feeders transport almost any material and come with a conveyor trough having a maximum usable width of 5500 mm.

Speed and vibration amplitude of the linear-motion feeders can be adapted to suit the specific product in order to minimise wear and optimise the distribution of the material transported.

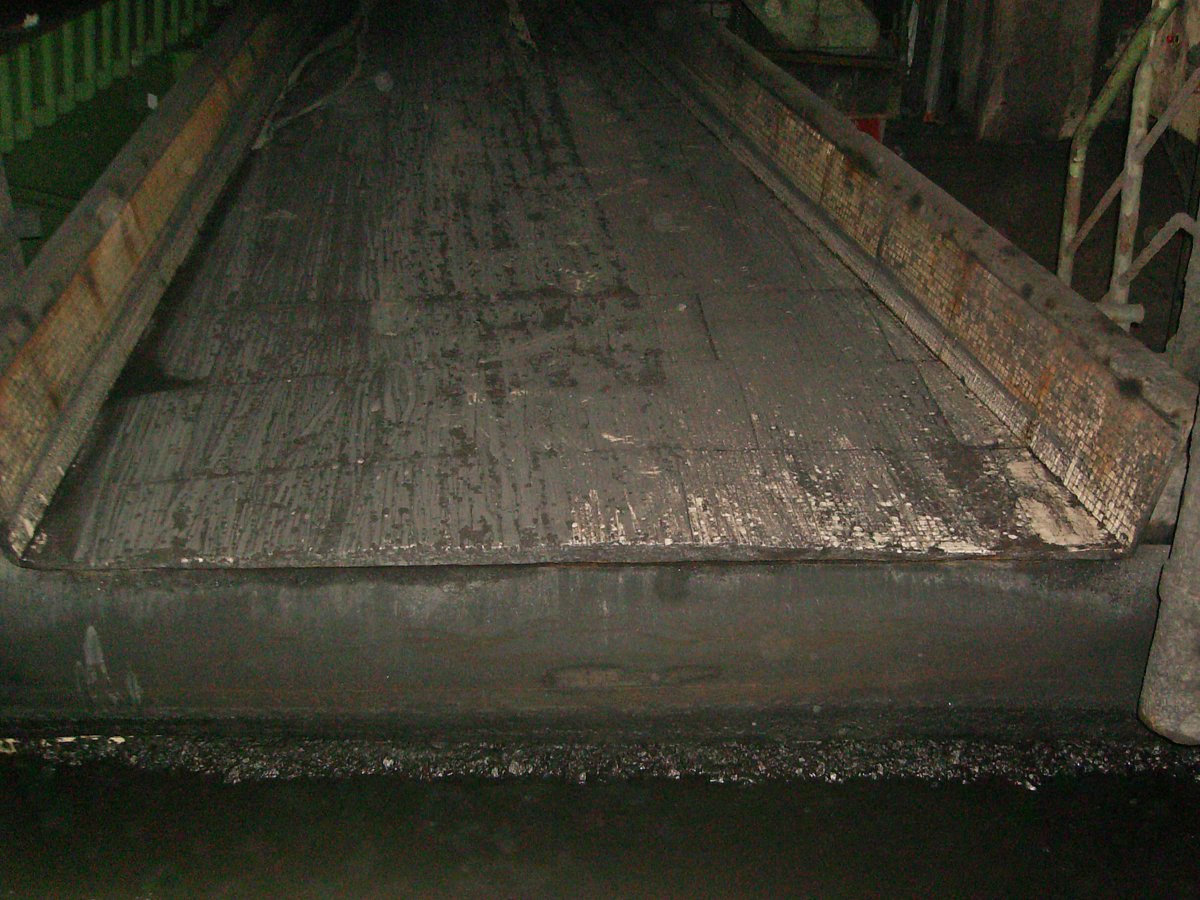

The channel box, consisting of side walls, cross-members and conveyor trough, can withstand all static and dynamic forces. The vibration generating system is not arranged at the centre of gravity of the vibrating machine; instead double unbalance gear units or unbalance motors are mounted on a drive bridge. The important thing is that the resulting force direction runs through the centre of gravity of the entire vibrating machine .

Linear-motion feeders are driven by a V-belt drive with intermediate transmission or by a direct drive through a universal joint shaft. Double unbalance gear units have an oil filling. Unbalance motors are grease-lubricated for life.

The entire vibrating machine is elastically supported against the substructure on spring elements. Here various systems of spiral compression springs, rubber buffers, vibration elements or air bellows are possible and, if necessary, combinable (hybrid suspension).

For dusty screening material we can, if required, supply channel conveyors with a dust cover. For hopper discharge channels hopper valve shoes, needle slide gates or suspensions can be supplied too.

The robust construction using and combining standard component parts ensures high flexibility and customer-focused solutions, on the one hand, and, on the other, enables the construction of machines with low-maintenance running time and a long service life.

A comprehensive range of accessories is available for all SIEBTECHNIK TEMA vibrating feeders. Whether it’s wear protection, counter-vibration frames, air suspension, dust covers, drive consoles, double unbalance gear units, hybrid suspension, unbalance motors or customer-specific special designs – with its decades of experience SIEBTECHNIK TEMA achieves the best result for your requirement.

Naturally our machines can be perfectly combined and offer the optimum solution as a package.

Ask us, we’re there for you.