Steinhaus Multotec Cyclones

With over 40 years’ experience in mineral and particle classification, We offer a complete range of standard and customised cyclones, constructed in various high-quality materials to cater to any application requirement. Our industry leading range of cyclones offers maximum separation efficiency and lower running costs, and is backed by our extensive application knowledge of the global mineral processing industry.

New field testing and cyclone design has resulted in a variety of cyclones that are lighter, more cost-effective, environmentally-friendly and require less energy to help customers lower their cost per ton in a lower footprint, sustainable plant operation.

The Multotec cyclone is an industry-proven product that has been carefully designed and specified to best suit operational and client requirements. Multotec also provides full technical support and service including a complete spare parts backup.

That’s why customers across the world use Multotec cyclones.

Features of our cyclone range:

- Made from high quality rubber, ceramics and polyurethane compounds

- Customised cyclone designs according to your unique specifications

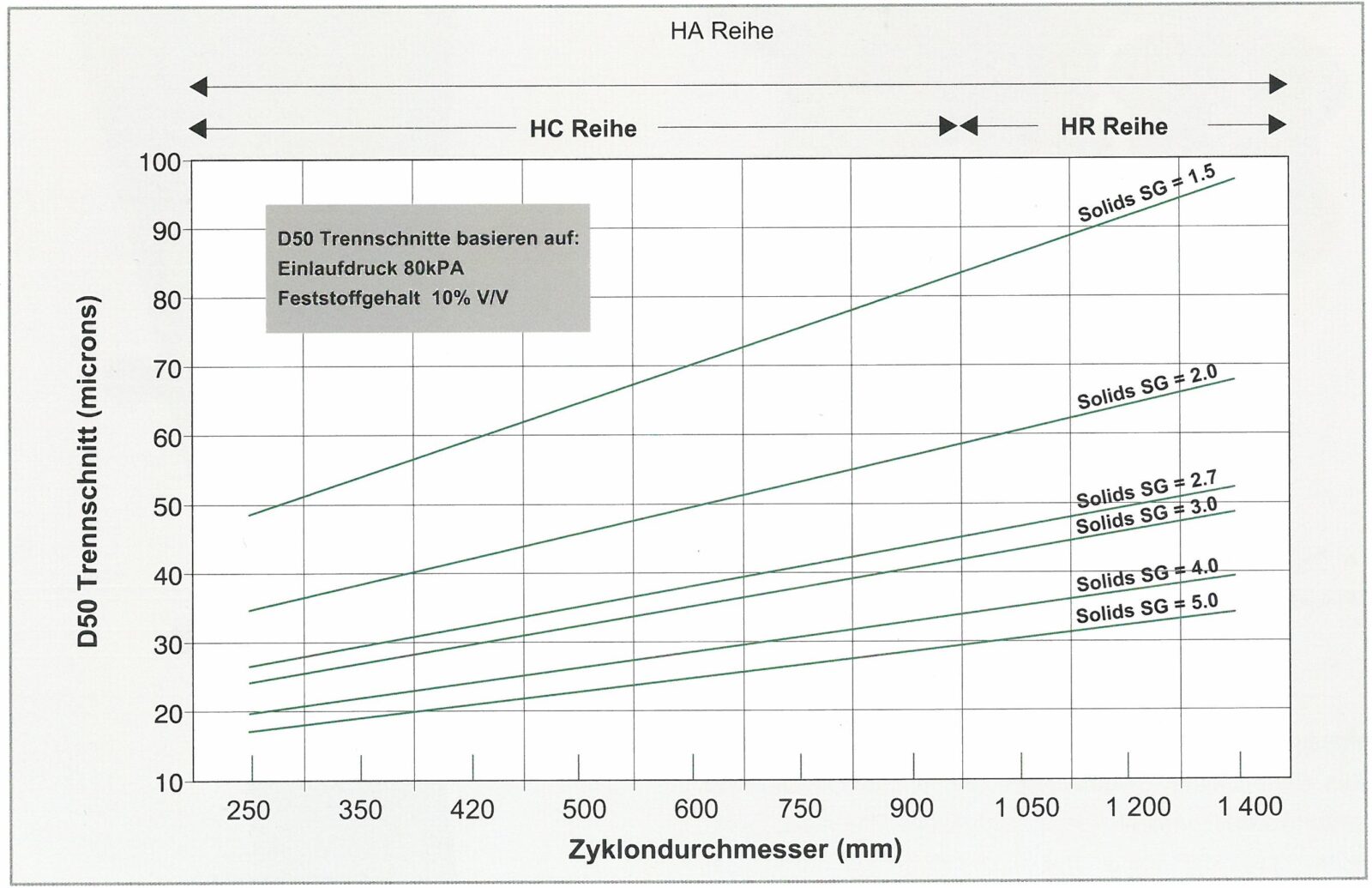

- Designed for both fine and accurate cut-points

- Reduced misplacement of product

- Abrasion and heat resistant materials that reduce wear

- High temperature and chemical resistant for harsh applications

- Maintenance and operating manuals are included with all new units excluding replacement units

Need a customised cyclone?

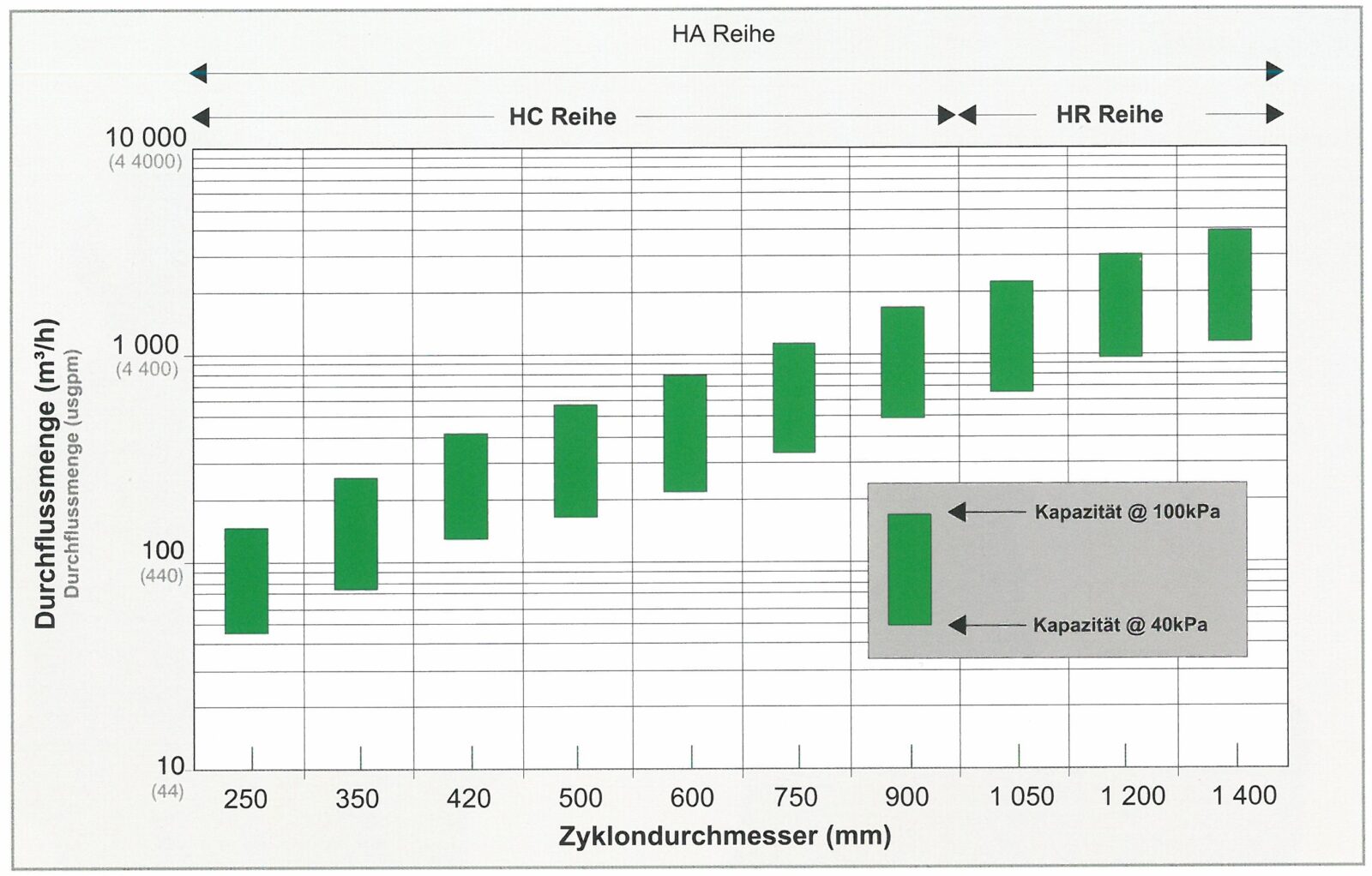

Multotec has a wide range of standard cyclone solutions ranging from units of 25 to 1 450 mm diameter in various grades and materials of construction. Our cyclones are selected and sized by an experienced process team to best suit clients’ needs. Should you need a tailored cyclone for specialised applications, Multotec can custom design and manufacture a cyclone to your precise requirements.

The innovation at the heart of the Multotec cyclone range:

We have revolutionised the mineral processing industry with its range of cyclones that feature the innovative scrolled evolute design. Through extensive testing and simulations, specialists of Multotec have proven that both the scrolled evolute and ribbon inlet designs have a higher capacity when compared to standard inlet designs. These designs substantially reduce vortex finder wear, thereby reducing operating costs while maximising cyclone efficiency.

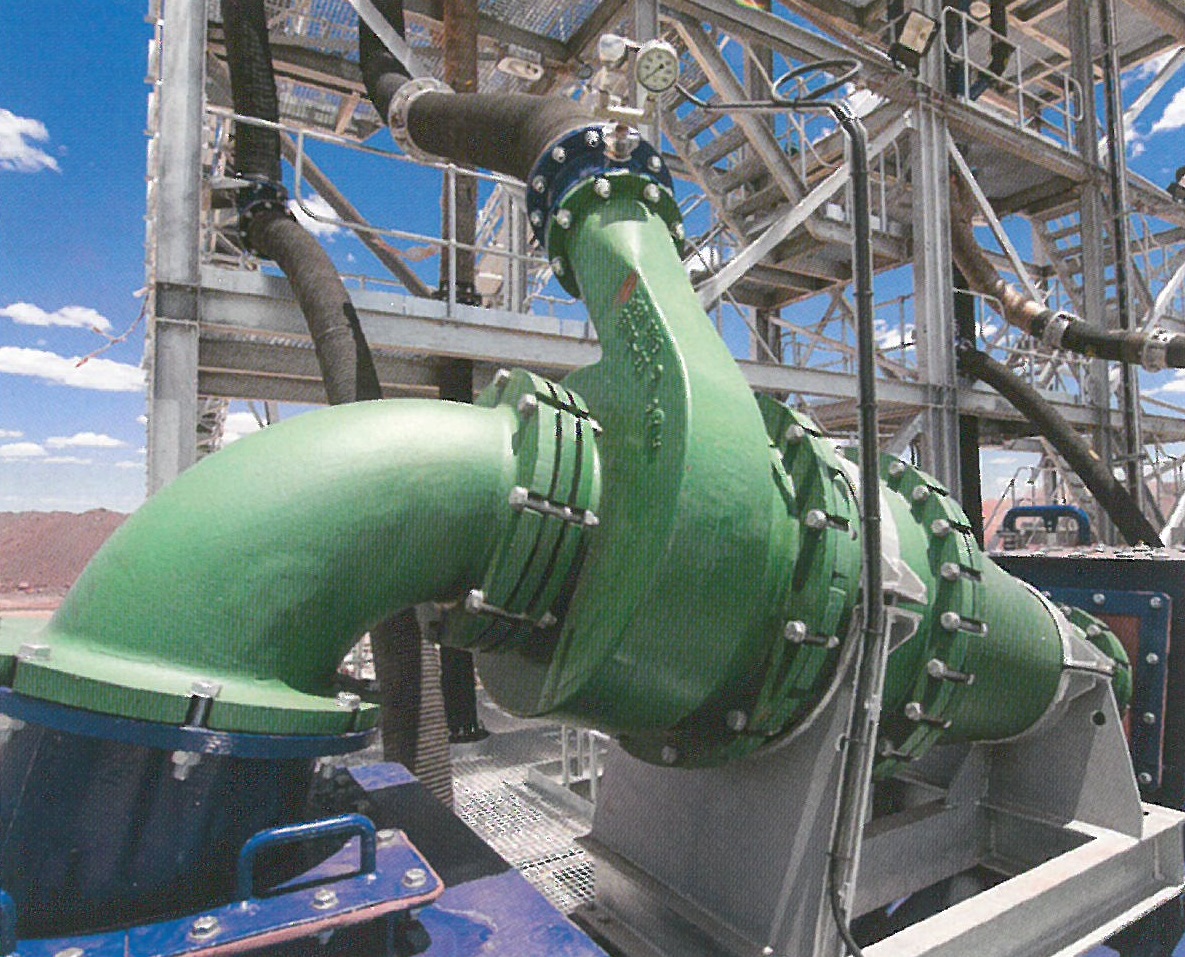

New HDPE Cyclone Overflow Elbows

Our factory Multotec has recently addressed customers’ requests in aggressive milling applications for longer-lasting overflow elbows with its new innovation: completely rubber-lined HDPE overflow elbows.

Traditionally, the wear on overflow elbows was very localised and easily prevented by the inclusion of a rubber overflow elbow sleeve. The 6 mm rubber sleeve was designed to fit inside the overflow elbow, just above the outlet of the inlet head. However in aggressive applications the wear point is exaggerated and therefore made the rubber sleeve less effective. Due to the HDPE manufacturing constraints, a longer sleeve cannot be fitted throughout the length of the overflow elbow. However, this constraint is now a thing of the past thanks to Multotec’s new innovation. By rubber-lining the entire HDPE elbow, the overall operating life of the overflow elbow is now extended. The fully rubber-lined elbows are lined with 6 mm thick natural rubber for all cyclone sizes up to 750 mm diameter. All cyclone sizes larger than 750 mm diameter will be lined with 10 mm thick natural rubber.

Siebtechnik Tema will still offer the unlined HDPE elbow and accompanying rubber sleeve for clients, as standard.