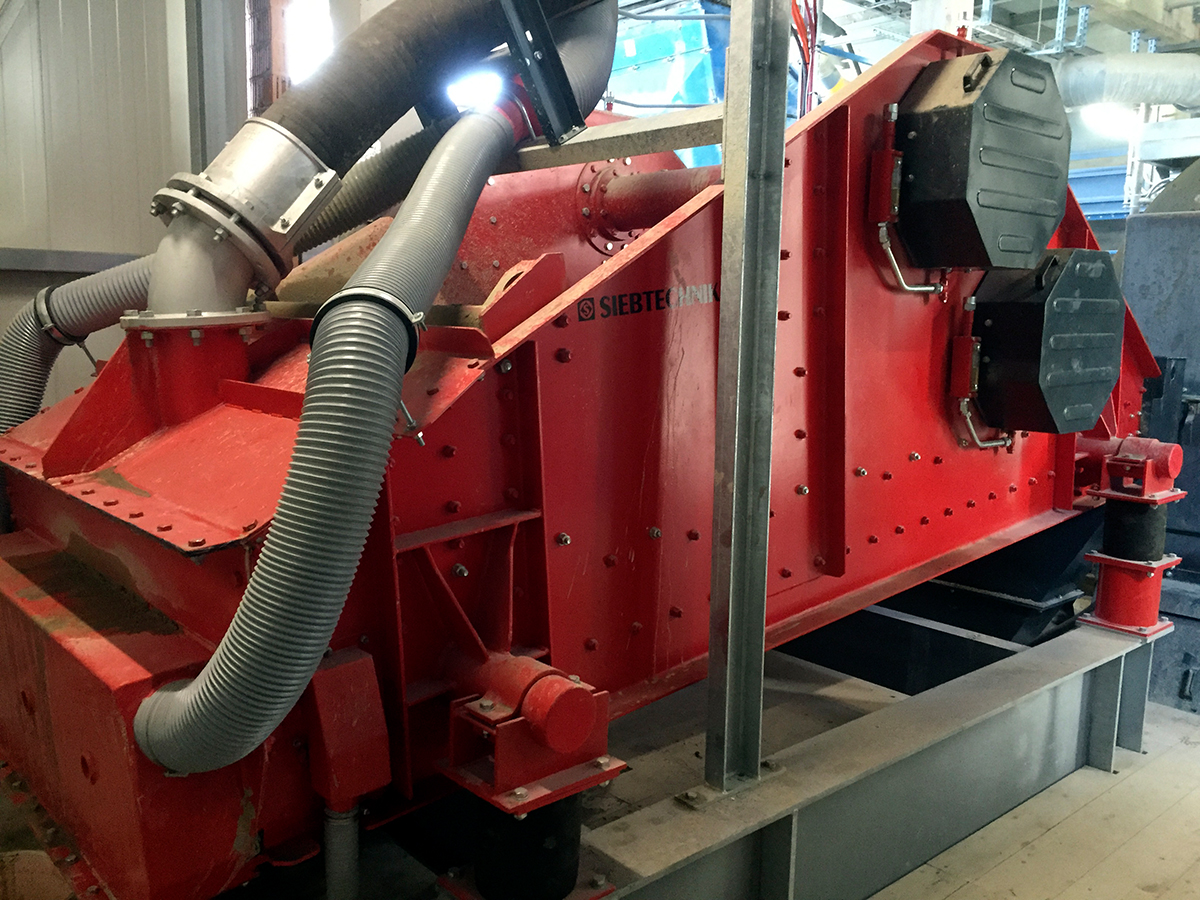

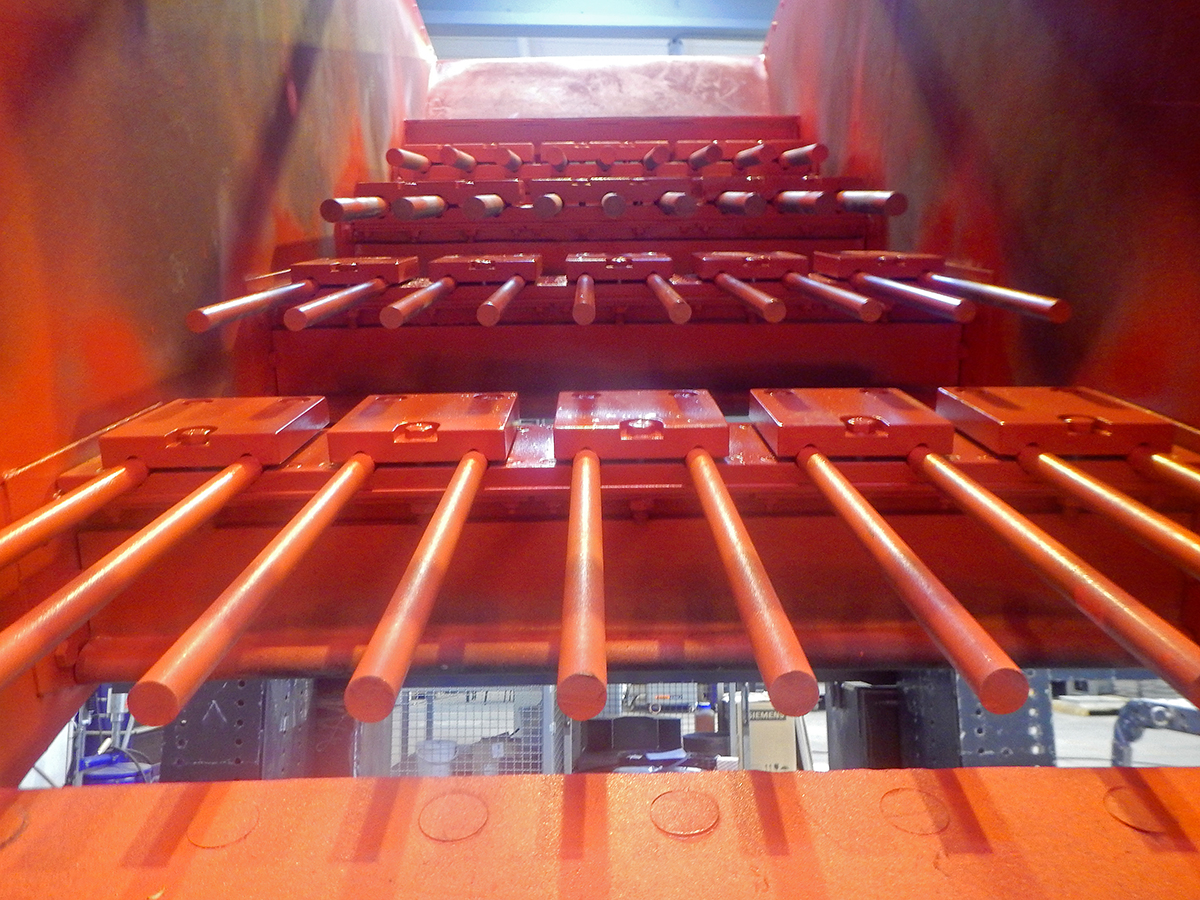

SIEBTECHNIK TEMA linear-motion screening machines are freely vibrating machines, that is, the vibration amplitude freely adjusts itself to suit the mass ratio of screen box and unbalance mass. Linear-motion screening machines are designed with a selectable steep (approx. 75°) or shallow (approx. 40°) throw angle and are therefore flexible with regard to the selection of the screen panel tilt, which ranges from upwards through horizontal to downwards. Examples are dewatering screens with an upwards tilt of between 3° and 5° and screening machines for classification that require a downwards tilt of up to approx. 40° (thin-layer screening).

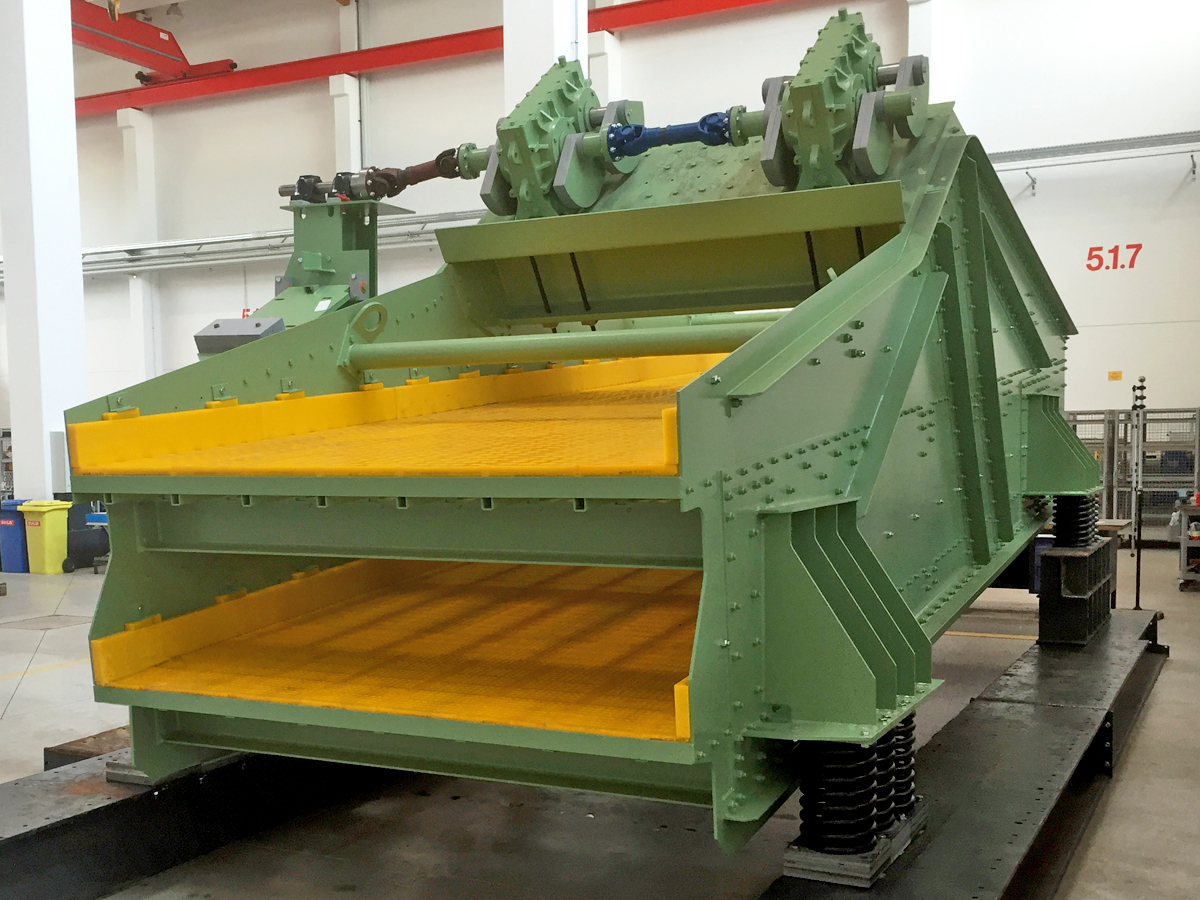

Our HG (double unbalance gear units), DWS (dual-shaft screen) and HR (unbalance motors) series screening machines offer separation sizes of between 0.5 and 300 mm and a screen area of approx. 1 to approx. 60 m². These machines can be set up for a vibration amplitude of between 2 and 14 mm, depending on the product. The screen set-up can comprise between one and three screen decks.

Speed and vibration amplitude of the linear-motion screening machine can be varied specifically to suit the product and so ensure a lastingly perfect screening result.

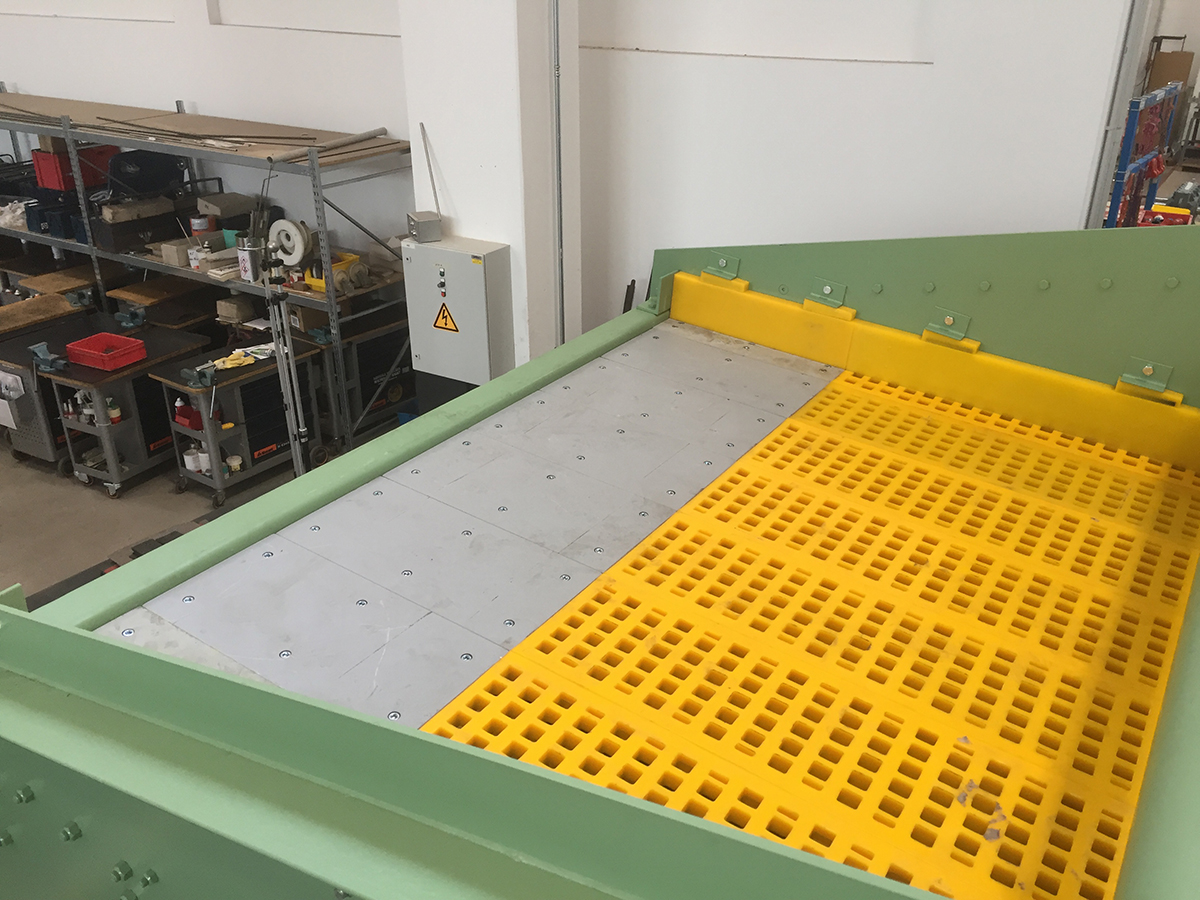

The screen box is set up to hold lengthways or crossways tensioned screen panels or for level screen decks and naturally also for system screen cloths by different screen cloth manufacturers.

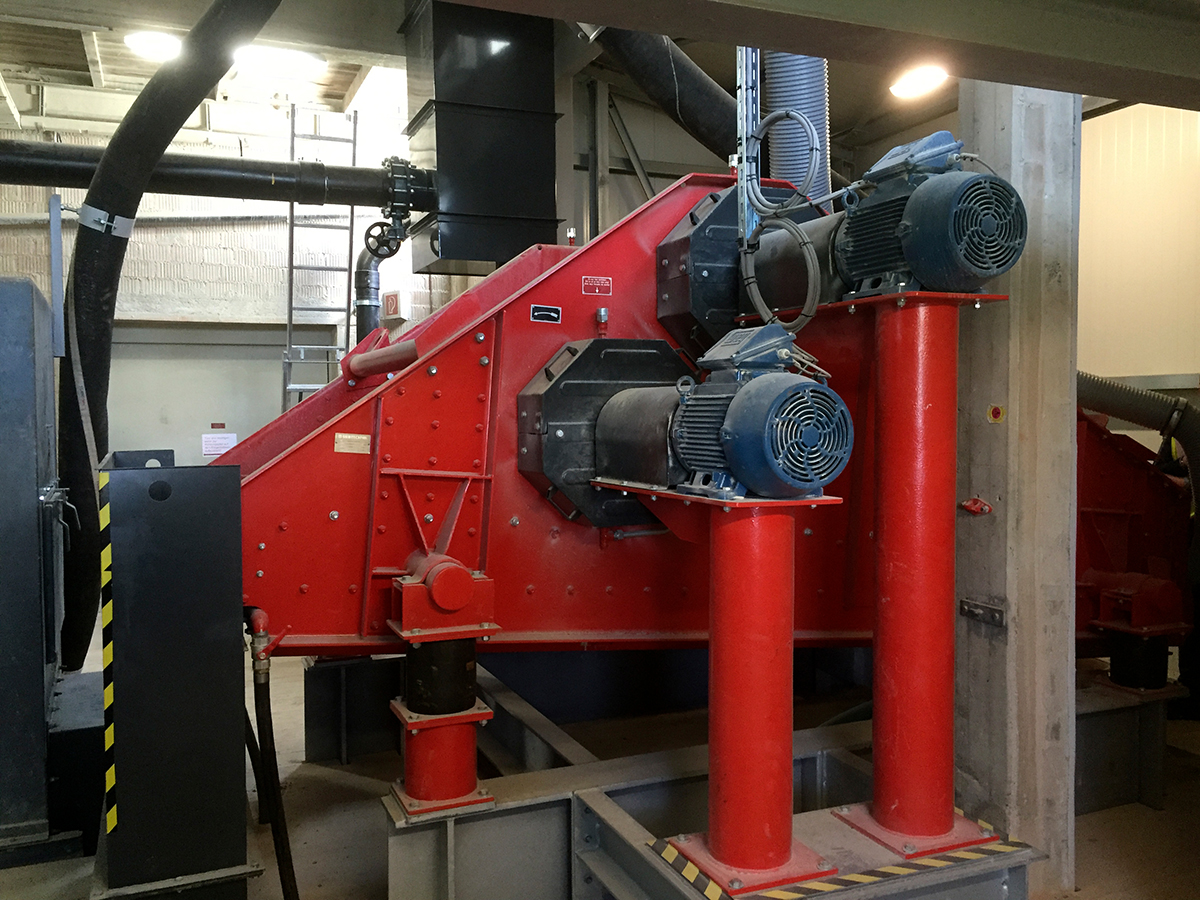

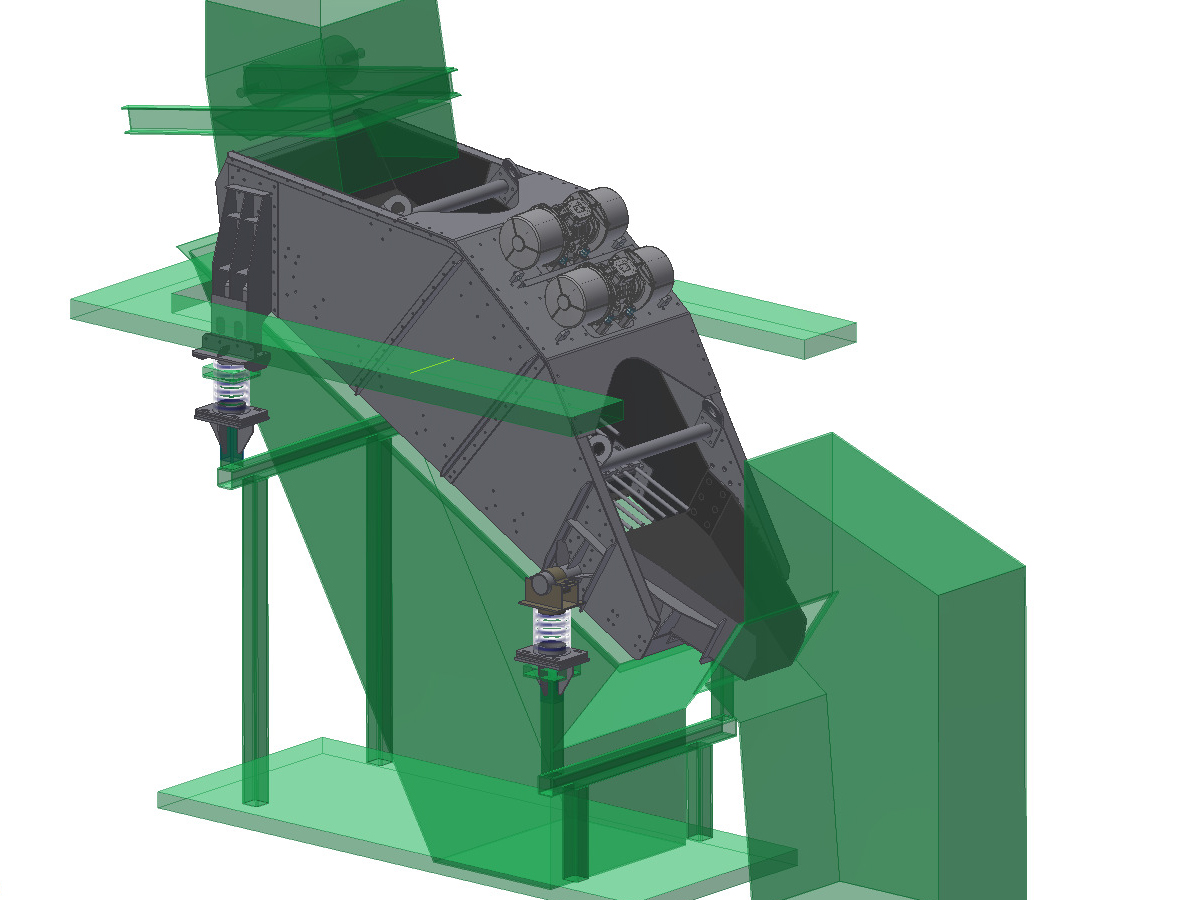

The screen box, consisting of side walls and cross-members, can withstand all static and dynamic forces. The vibration generating system is not arranged at the centre of gravity of the screen box. Double unbalance gear units or unbalance motors are mounted on a drive bridge. The important thing is that the resulting force direction runs through the centre of gravity. The same applies to the position of the two drive shafts on dual-shaft screening machines.

The linear-motion screening machine is driven by V-belt drive with intermediate transmission or by a direct drive with a universal joint shaft. Double unbalance gear units have an oil filling. Unbalance motors are grease-lubricated for life. Double shaft screens are optionally oil- or grease-lubricated.

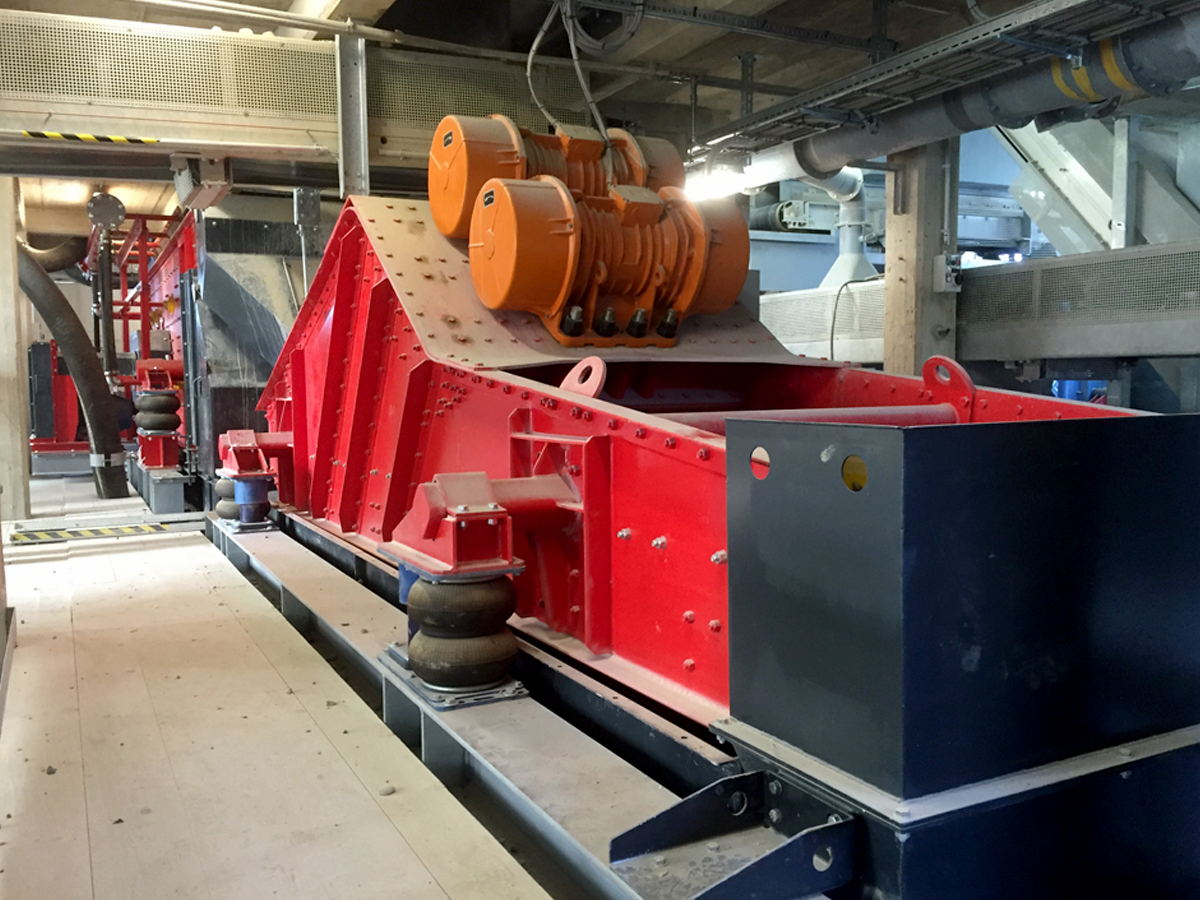

The screen box is elastically supported against the substructure on 4 spring elements. Here different systems of helical compression springs, rubber buffers, vibration elements or air bellows are possible and, if required, combinable (hybrid suspension).

For dusty screened material we supply on request linear-motion screening machines with a dust cover or a closed dust protection box. Individually adapted screening aids in the form of beating devices or spraying systems are also available.

The robust construction using and combining standard component parts ensures high flexibility and customer-focused solutions, on the one hand, and, on the other, enables the construction of machines with low-maintenance running time and a long service life.