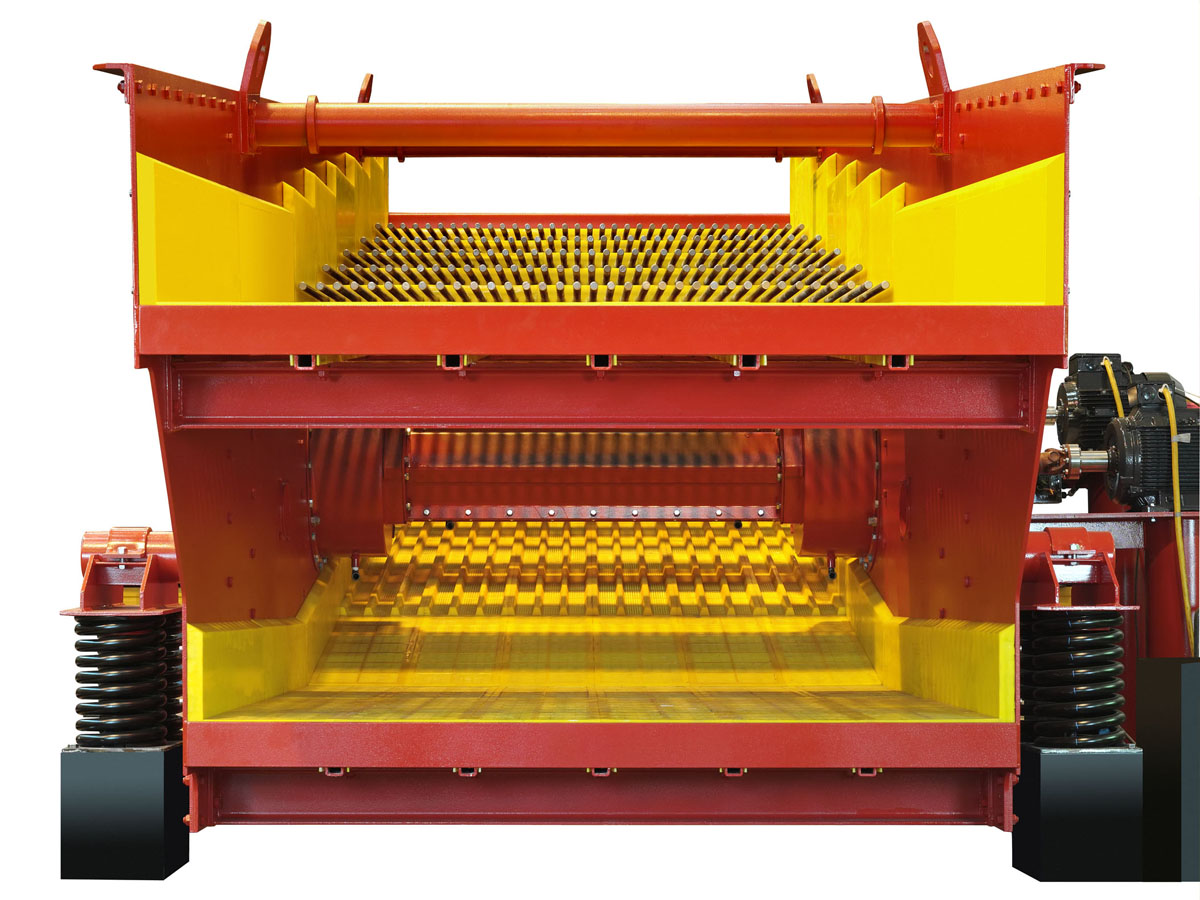

Elliptical-motion screening machine

The king class of classifiers and up to any task – mechanical or electronic

The elliptical-motion screening machine combines the advantages of linear- and circular-motion screen as well as enabling space-saving horizontal installation and high material throughput.

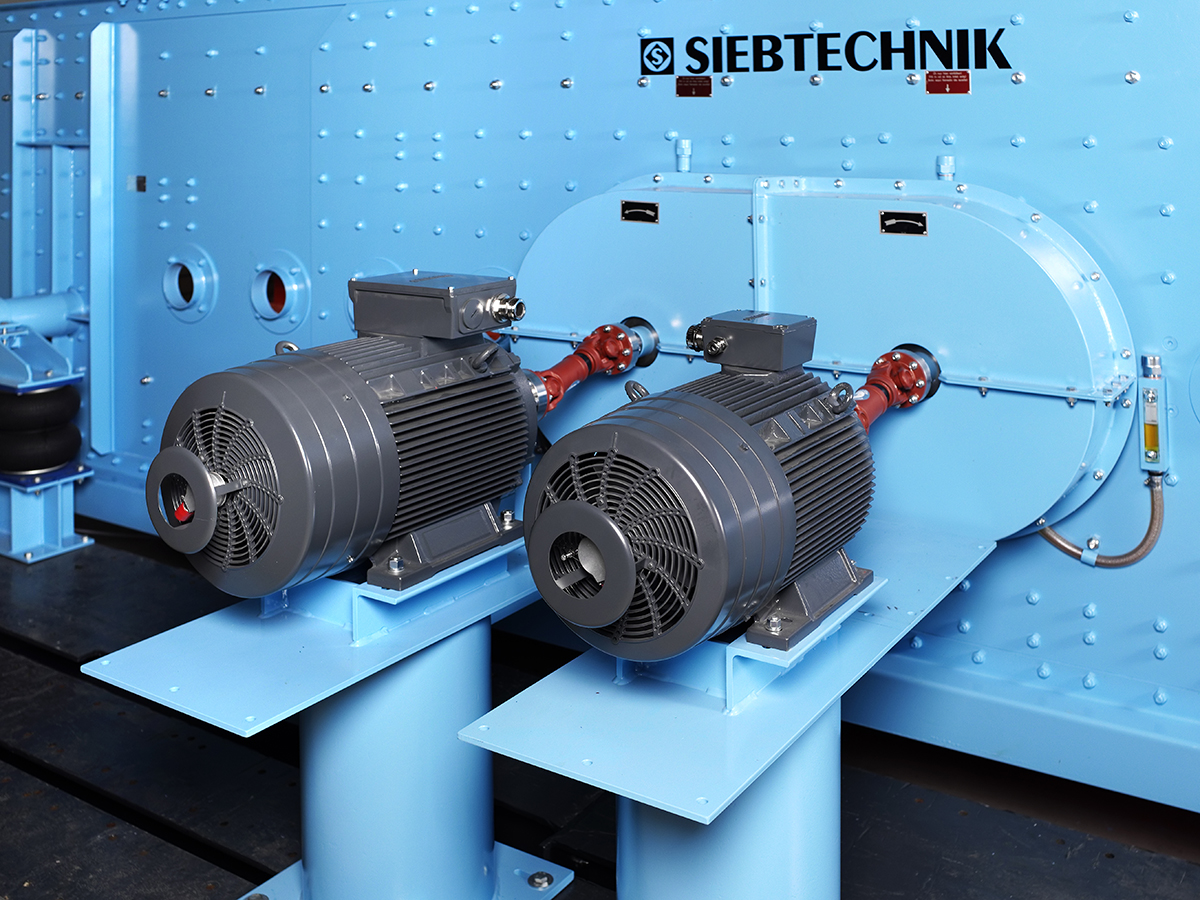

Both mechanical and electronic elliptical-motion screens can be selectively varied and adapted to operating conditions. This is done by, amongst other things, altering the throw angle essential for transport speed and by adaptation of parameters important for acceleration of the machine, such as vibration amplitude and speed.

The electronic elliptical-motion screening machine enables the speed and the throw angle to be adjusted while the machine is running: adjustment can be done manually on a touch panel or fully automatically, via a profibus integrated into the plant control system – without having to stop the machine at all!

Our electronic elliptical-motion screening machines respond to changing operating situations easily and without any intervention whatsoever by you. So fluctuating feed quantities, automatic cleaning and ejection of terminal grains in programmed cycles are no problem. A consistent screening result is lastingly guaranteed. The electronic components are carefully selected for usual harsh operating conditions and are not prone to defect.

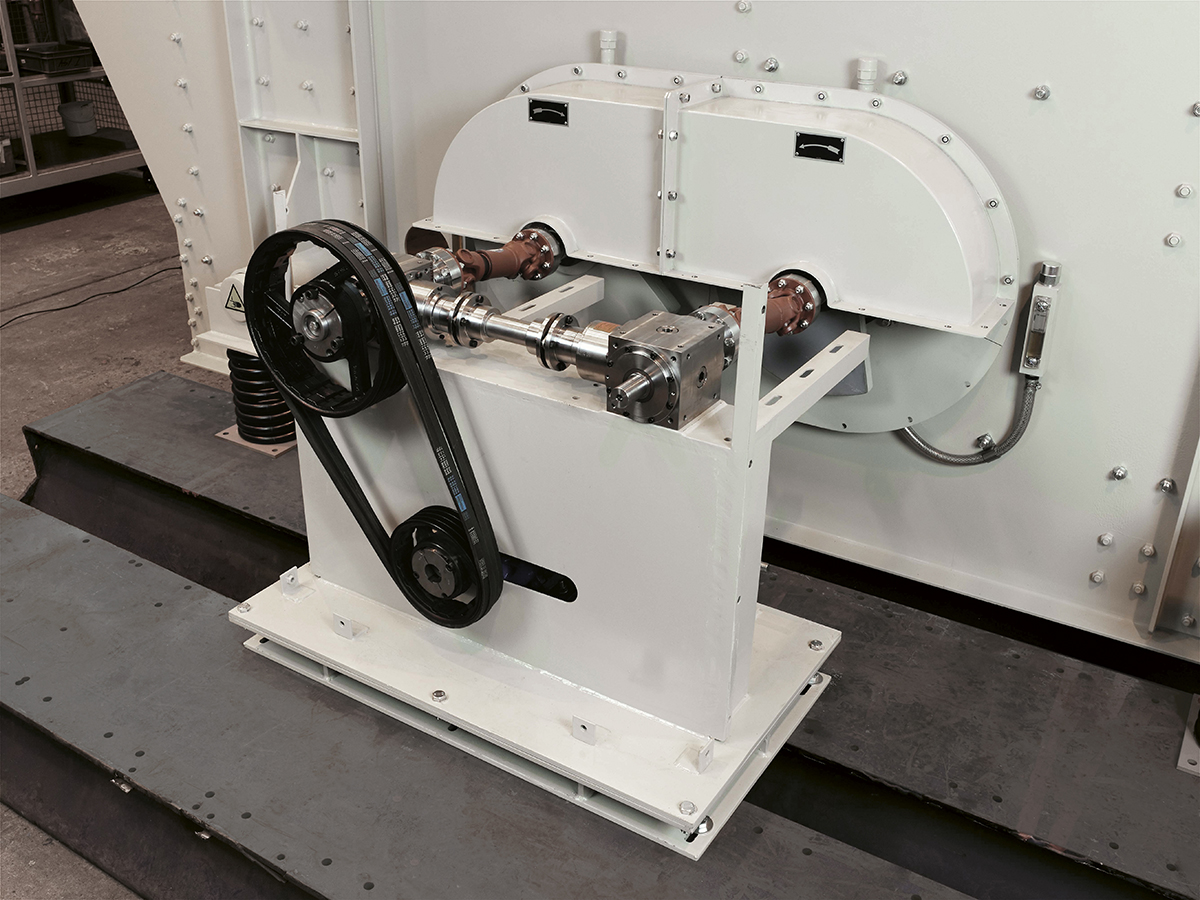

Just as flexible as the electronic elliptical-motion screening machine is the mechanical elliptical-motion screening machine, but it is adjustable in its most essential vibration parameters only when at a standstill.

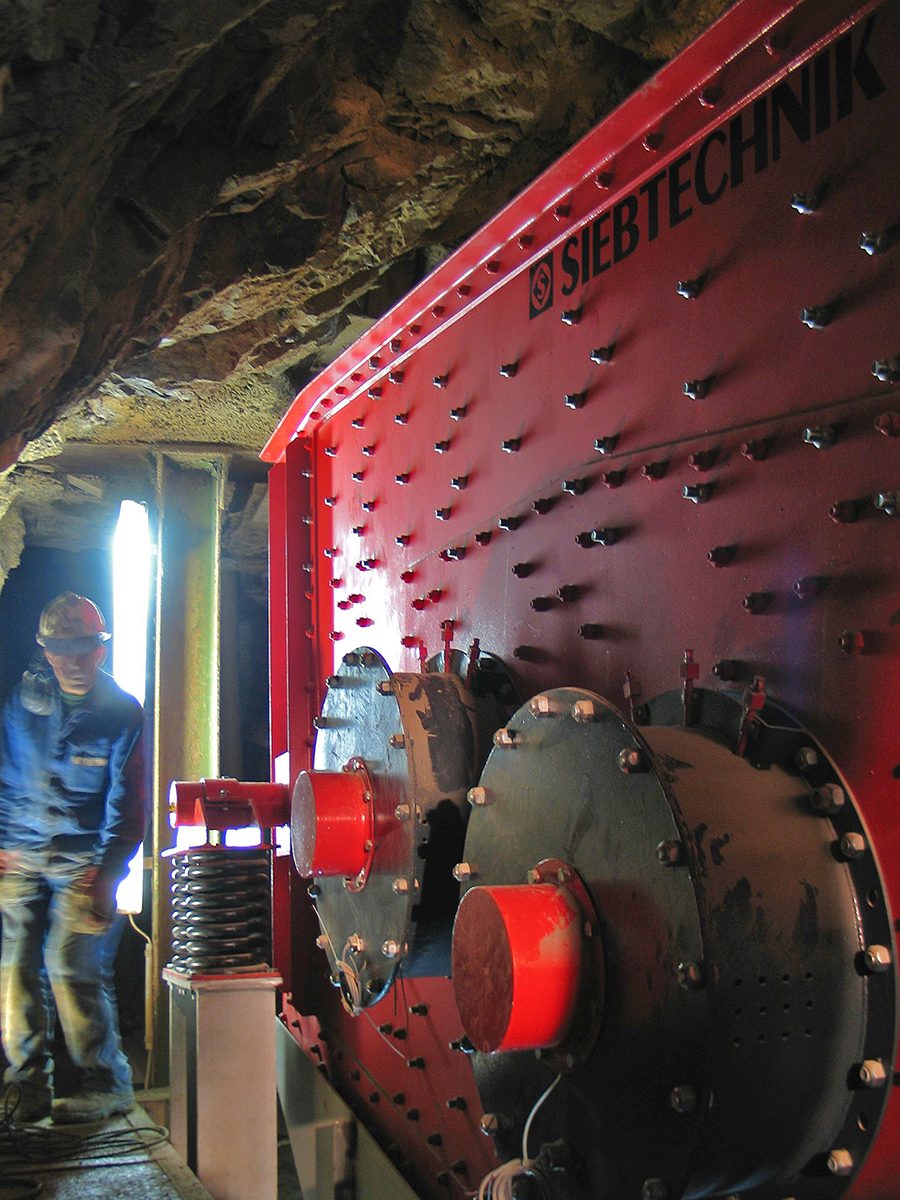

SIEBTECHNIK TEMA elliptical-motion screening machines guarantee flexibility in the production process and ensure consistent product quality.

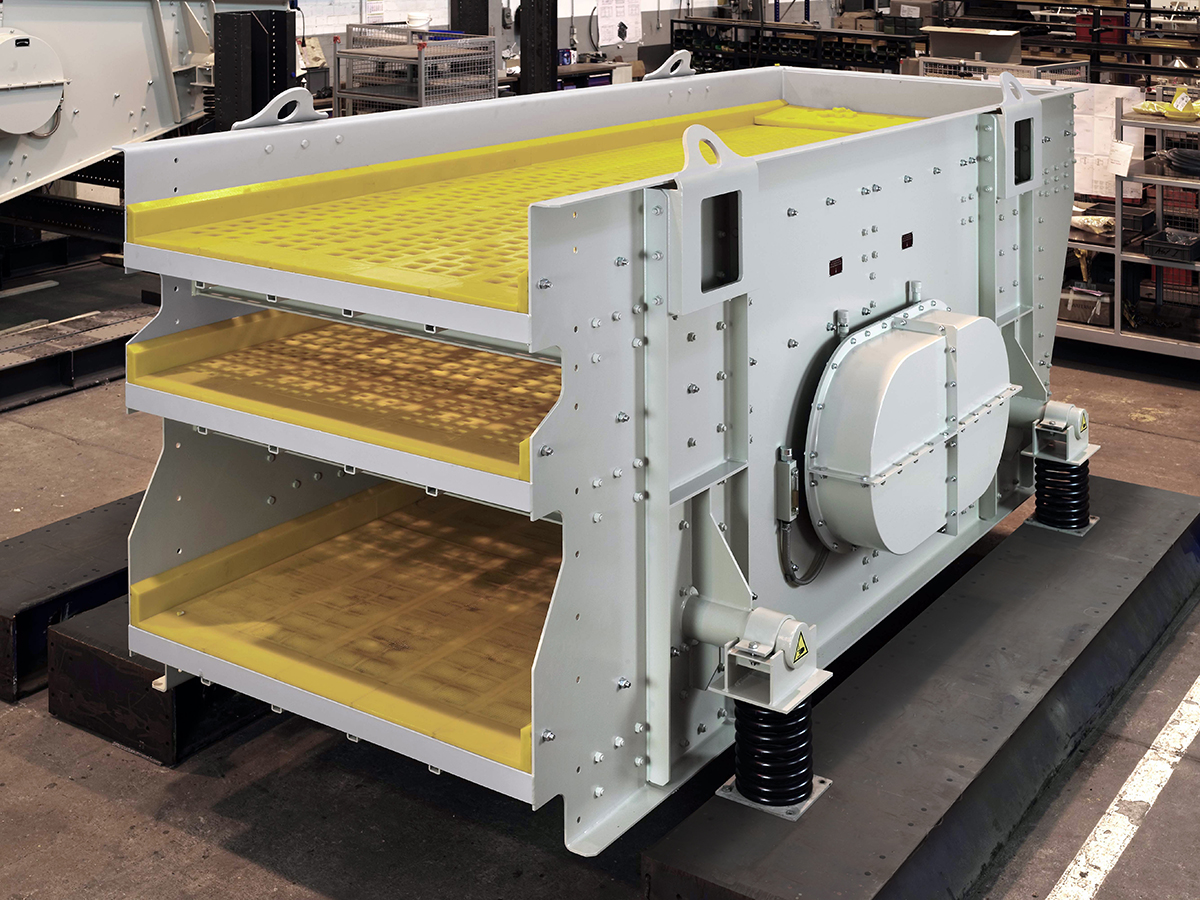

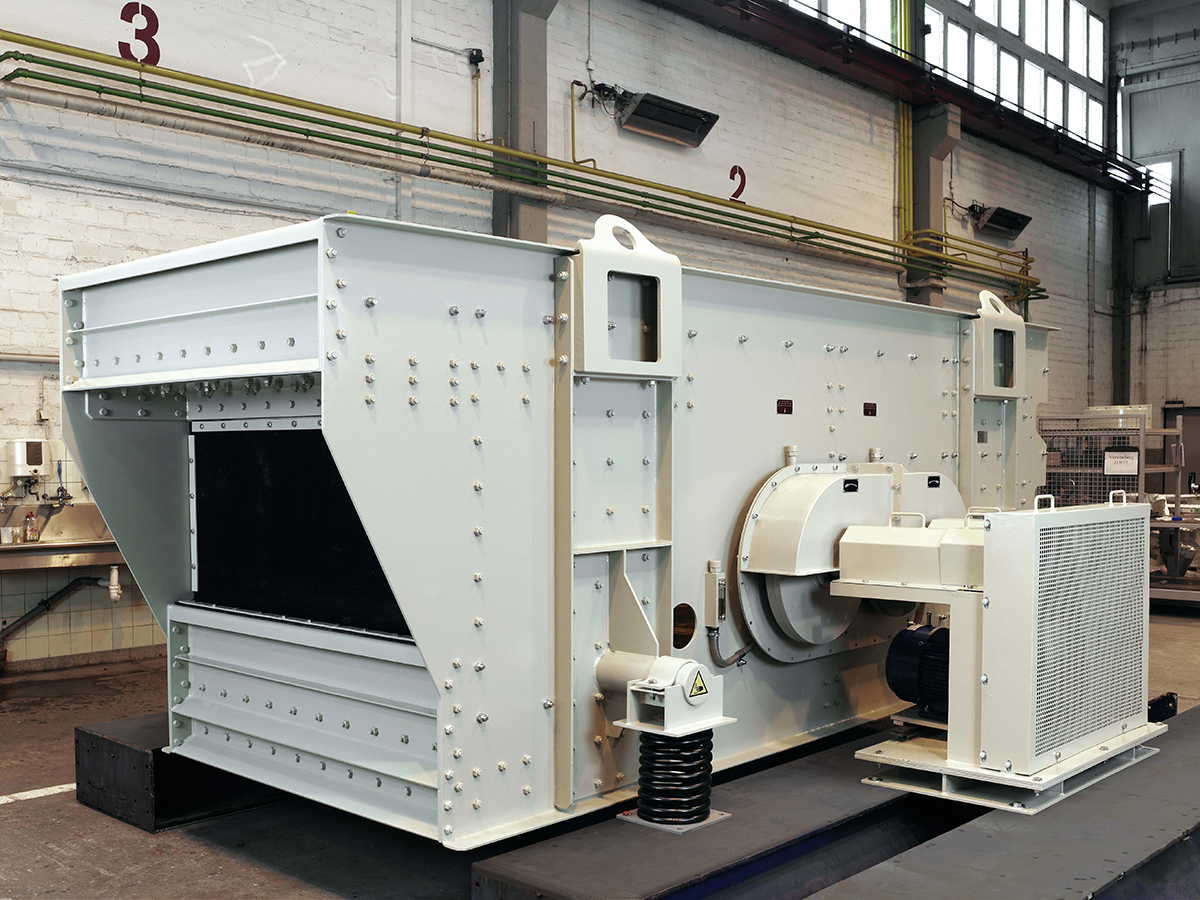

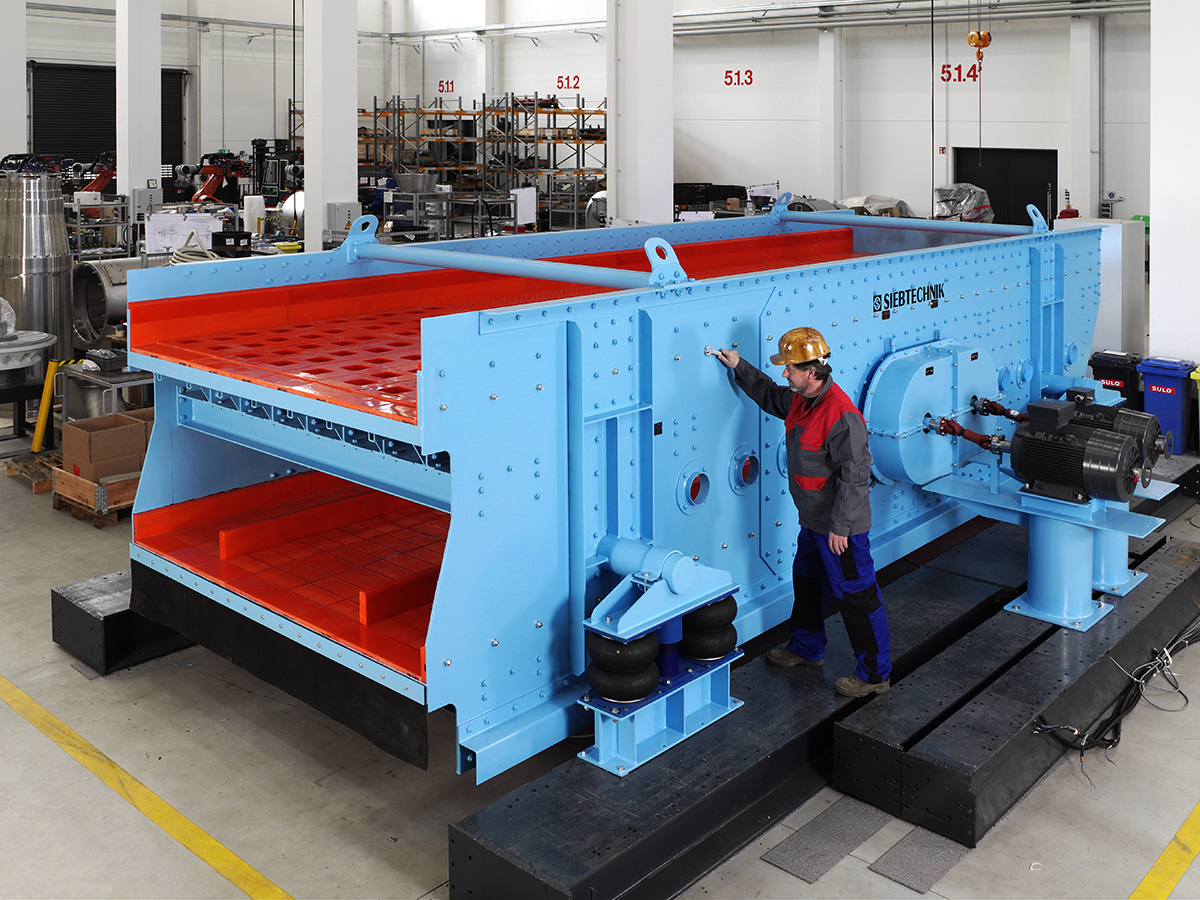

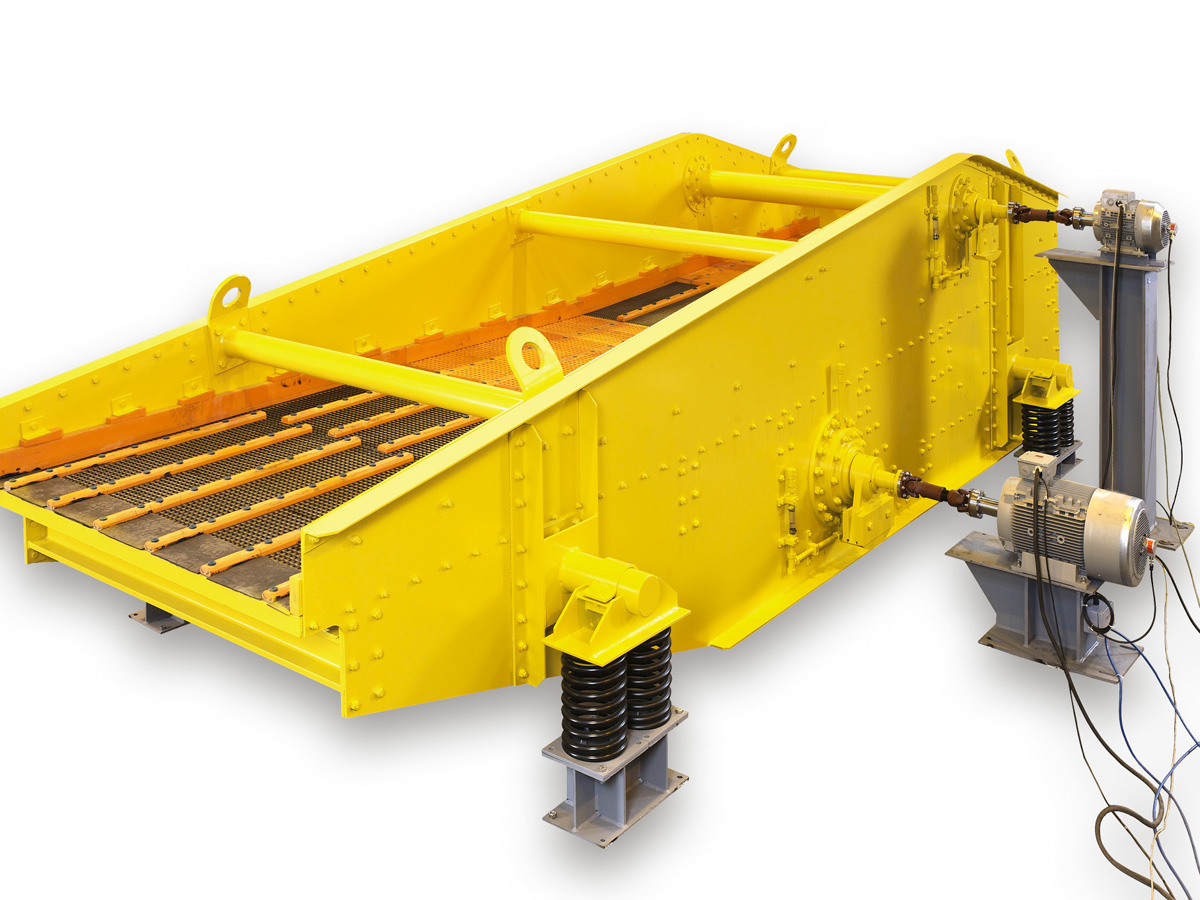

Operational behaviour and mechanical characteristics

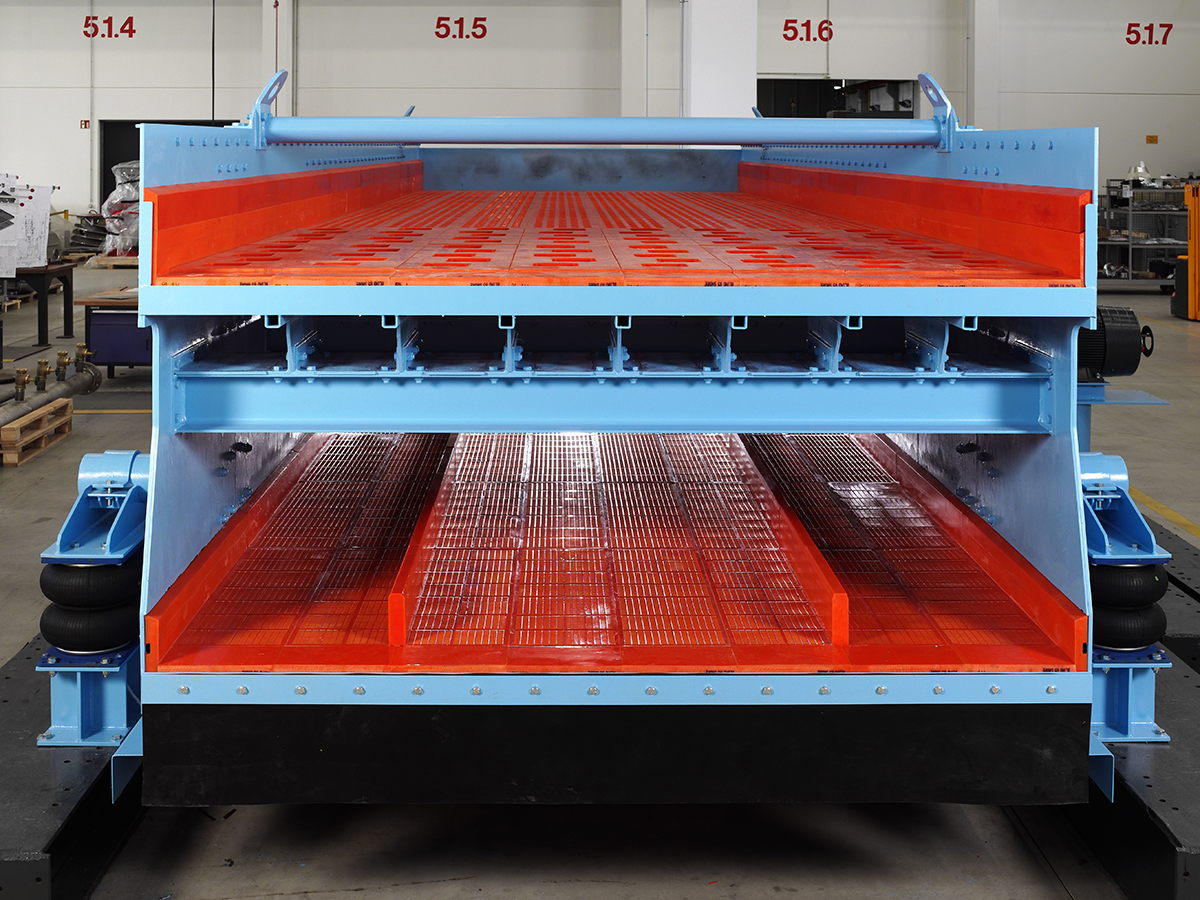

Our type E (shaft with unbalance mass) and type EZ (cell drive) elliptical-motion screening machines offer separation sizes of between 0.8 and 300 mm and a screen area of between 0,6 and approx. 60 m². The machines can be set up for a vibration amplitude of between 6 and 12 mm (main axis), depending on the product. The machines and therefore the screen panel are normally installed horizontally; the screen set-up can comprise between one and three screen decks.

The screen box is set up optionally to hold lengthways or crossways tensioned screen panels or for level screen decks and naturally also for system screen cloths by different screen cloth manufacturers. For dusty screening material we supply on request elliptical-motion screens with a dust cover. Also available are individually adaptable screening aids in the form of beating devices or spraying systems.