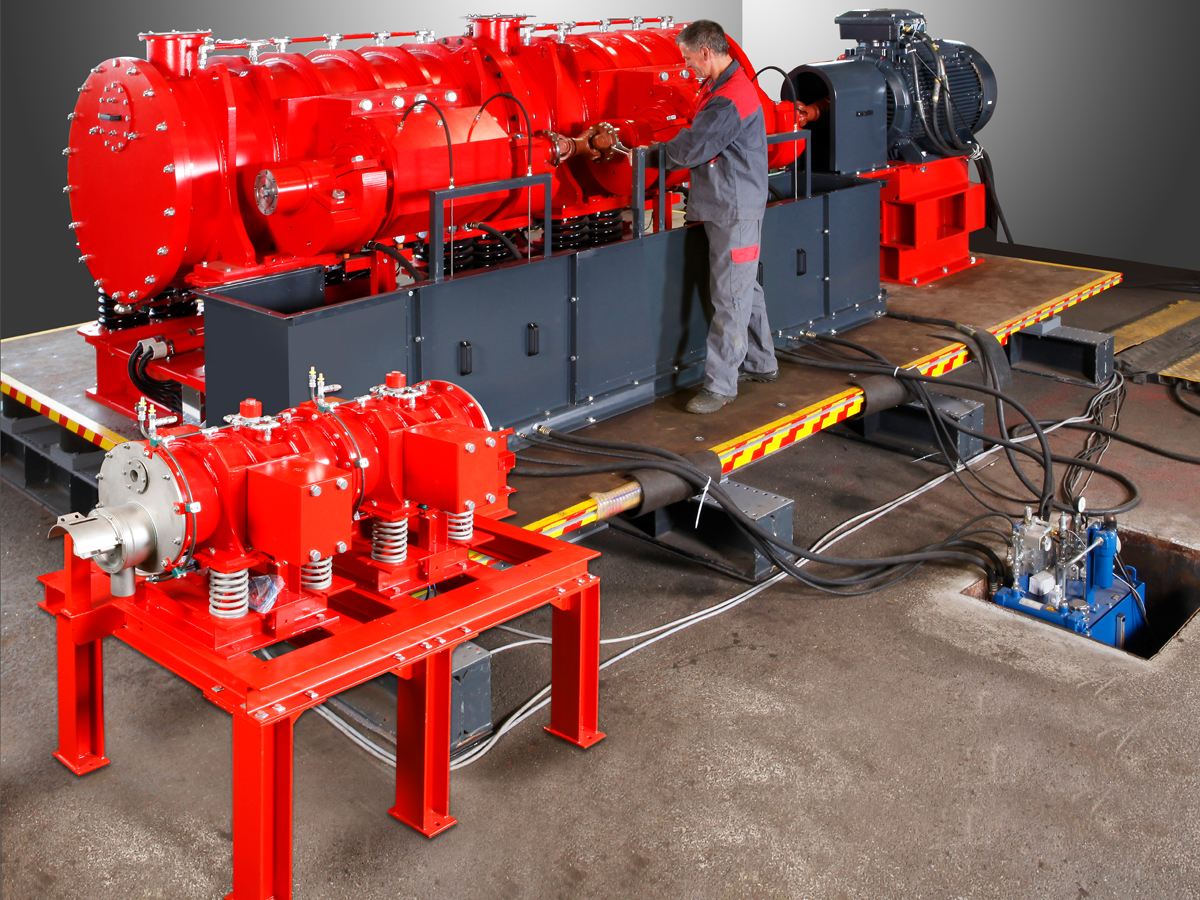

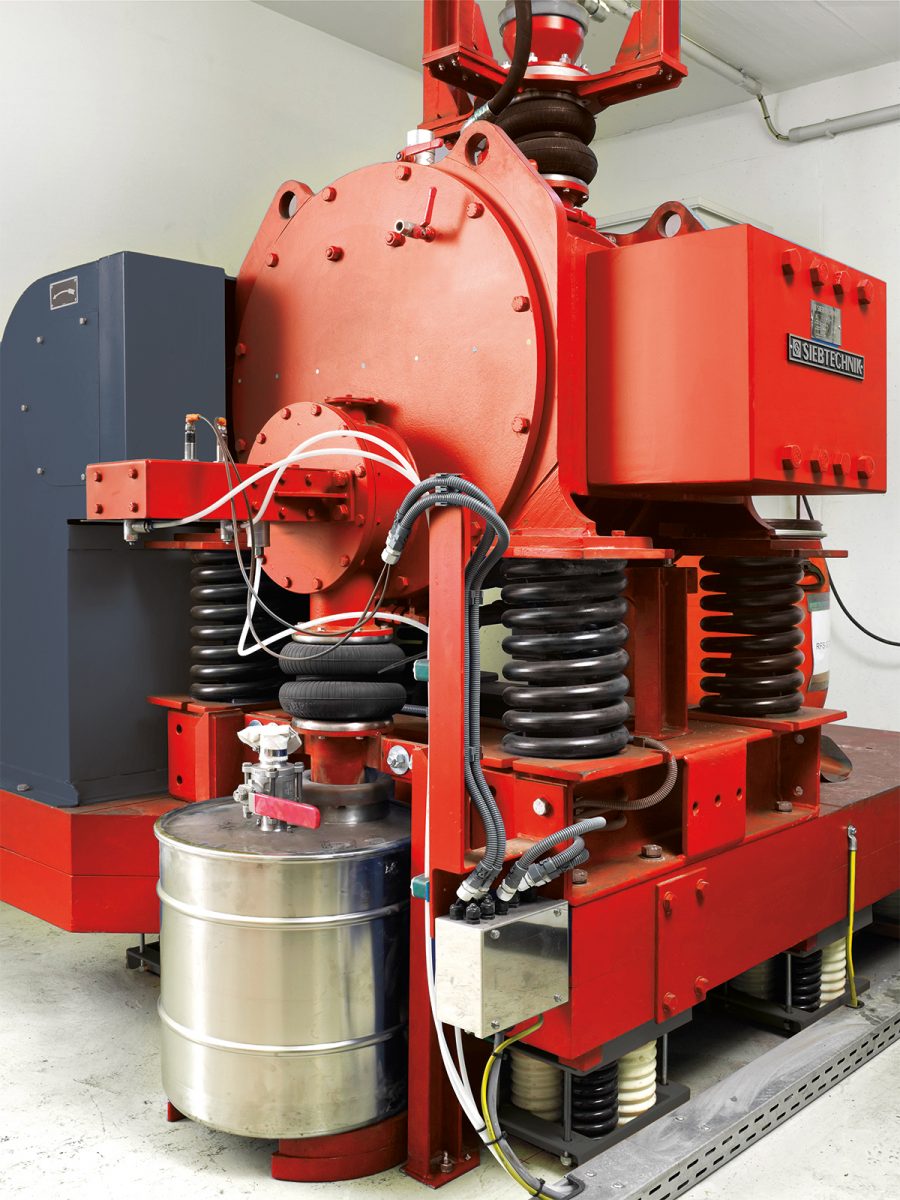

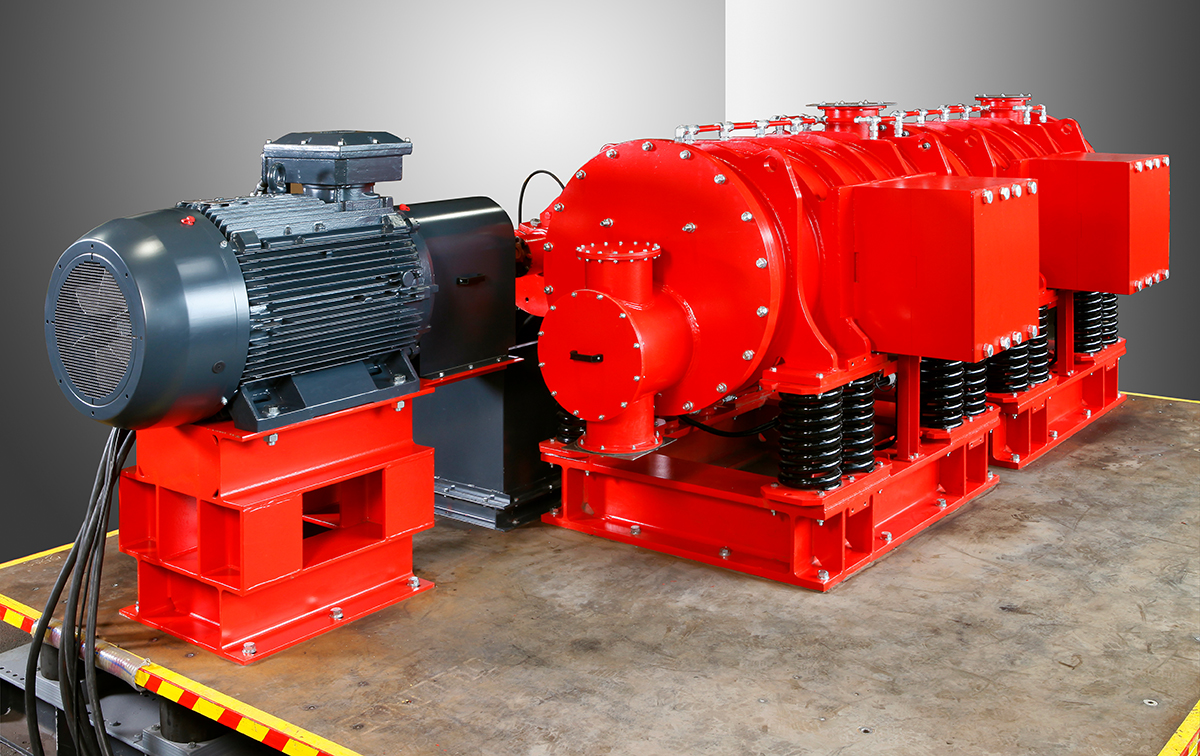

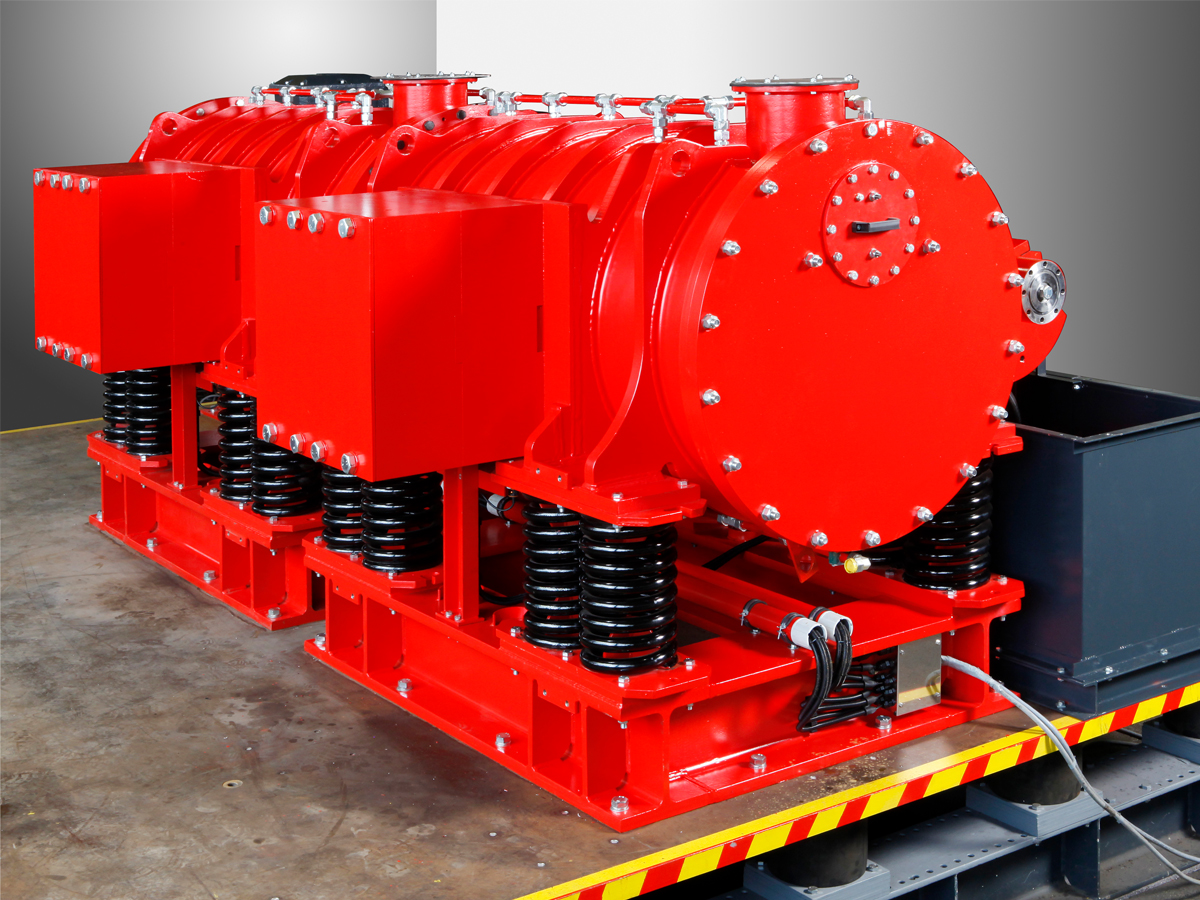

The SIEBTECHNIK TEMA eccentric vibrating mill is of modular design and basically comprises

- the cylindrical grinding vessel

- helical springs

- the base frame

- the grinding media

- the exciter unit

- the counter weight

The mill is set – via the direct three-phase drive and the exciter units – into inhomogeneous vibrations, which lead to the already mentioned high energy utilisation.

The mill is filled with feed material via a nozzle at the highest point of the grinding vessel and the output at the lowest point at the other end of the grinding vessel. A perforated metal plate in the discharge prevents the grinding media from passing through.

Different output systems enable the ESM to be equipped with the following types of operation.

- Continuous operation

- Batch operation

- Automated batch operation

SIEBTECHNIK TEMA produces customized eccentric vibrating mills especially for the particular application concerned. Available options include:

- Lining of the grinding vessel with wear-resistant lining made of special steel, ceramic or elastomers

- Grinding-media as balls, rods or Cylpebs in the most varying materials

- Cooling or heating through a double-walled grinding jacket

- Sound absorbing hood

- Opposed-action frame

- Inertisation with protective gas; vacuum; ATEX

- Complete plants including the necessary periphery

The ESM has convincingly proven its performance in the most varied applications and feed materials in the field of mechano-chemical activation and micro-grinding, including in the

- Automotive supply industry

- Pharmaceutical production

- Building industry

- Biomass preparation

- Chemical industry

- Ceramic industry

- Animal food industry

- …

In mechano-chemical activation, highly reactive conditions are generated, resultant in crystalline systems with impacting load. Generally, brittle materials have a crystalline structure, which prior to comminution represents the lowest-energy condition.

With mechanical load from impact, this crystal structure is partly destroyed and the incorporated energy stored.

This result in highly reactive conditions, which lead, for example, to

- an increase in reactivity,

- an improvement in solubility,

- magnetic properties,

- conductivity

- and other physical properties.

One peculiarity are the reactions of various crystalline systems with each other, whereby through solid-state reactions new materials come about with specific properties. Under these circumstances, the eccentric vibrating mill undertakes the role of a mechano-chemical reactor.

Micro-grinding in the eccentric vibrating mill likewise follows specific principles.

Here, fineness of 0 – 5 μm can be attained depending on the product and grinding duration, and fibrous materials developed.